FIBER PROCESSING MACHINES

SWEDISH QUALITY MACHINES SINCE 1977

NW-400 bale opener

The NW-400 bale opener is used for short and medium length fibers. It has double horizontal conveyor and can be loaded with full bales of

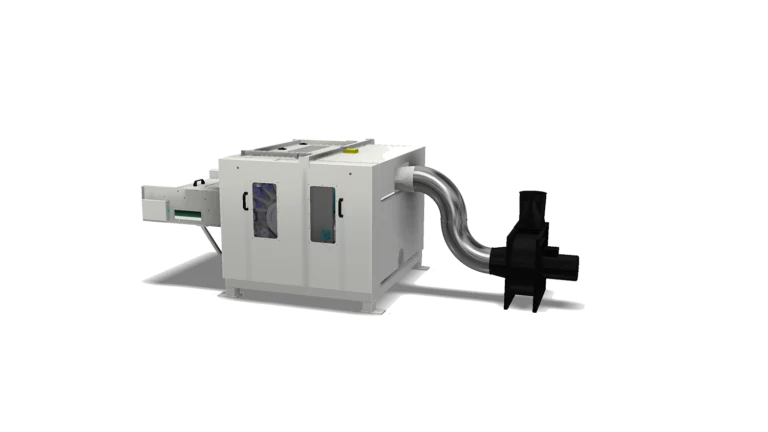

NW-420 fine opener

NW-420 fine opener Type RK The RK fine opener uses horizontal infeed conveyor followed by 2 feed rollers controlled by a frequency drive. It has

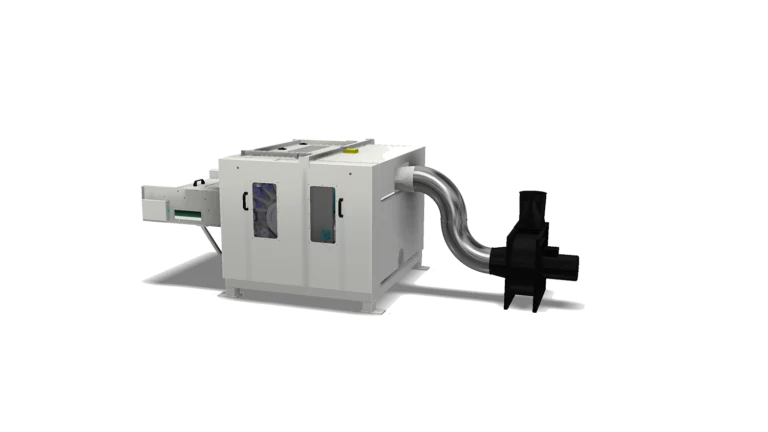

NW-421 fine opener

NW-421 fine opener Machine infeed is done by a horizontal infeed conveyor followed by 2 feed rollers controlled by frequency drive. The NW-421 fine opener

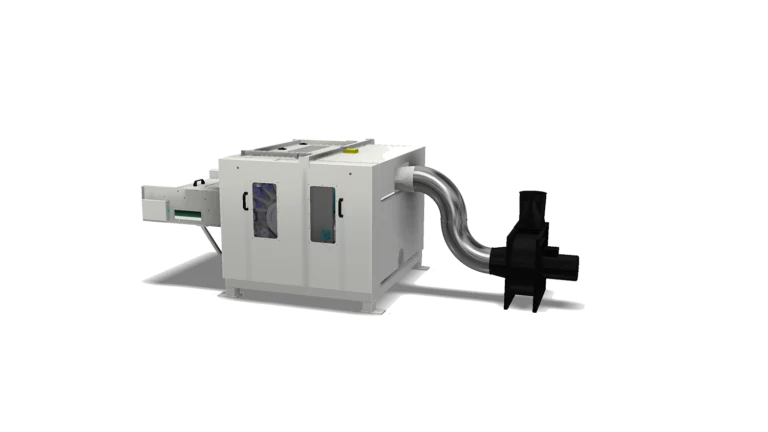

NW-423 fine opener

NW-423 fine opener Machine infeed is done by a horizontal infeed conveyor, followed by 2 feed rollers controlled by a frequency drive. The NW-423 fine

NW-440 universal feeder

The NW-440 machine is specially developed for feeding materials that doesn’t fit to be fed by traditional bale opener. (For example: foam chips, some recycled

NW-480 filling line

The NW-480 is a blow filling line scale unit with scale pan type weighing system. Best fitted for use of heavy filling materials (for example

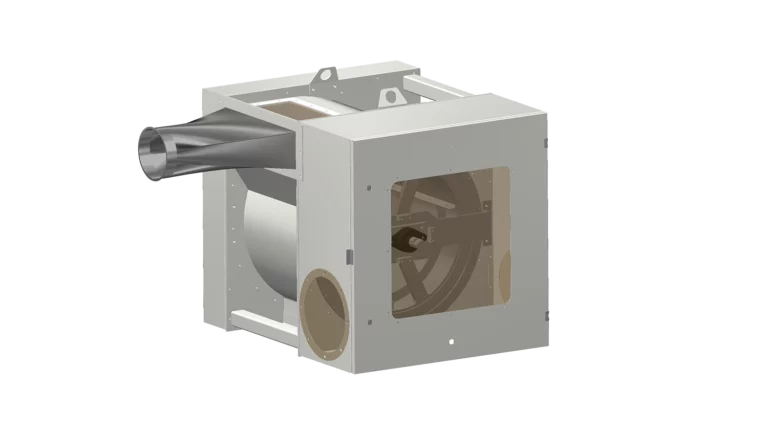

NW-520 fiber condenser

A device to separate fibers from pneumatic transport system without air pressure. Alternatively, can be used for dust separation. Technical data Two standard sizes 1000mm

NW-540 intermediate silo

Fibers are inserted from the top by pneumatic transport into the NW-540 silo system. Two feeding rollers and a spike roller will feed out the

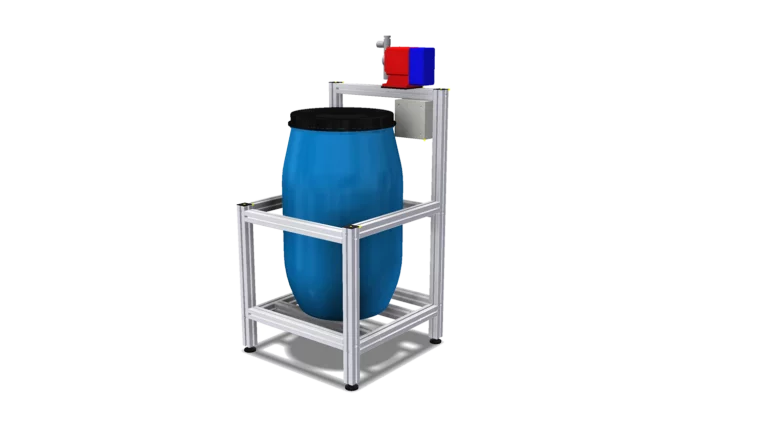

NW-580 anti-static dosing and spraying

The bale opener is used for short and medium length fibers. It has a double horizontal conveyor. A device consisting of reservoir for 60 l

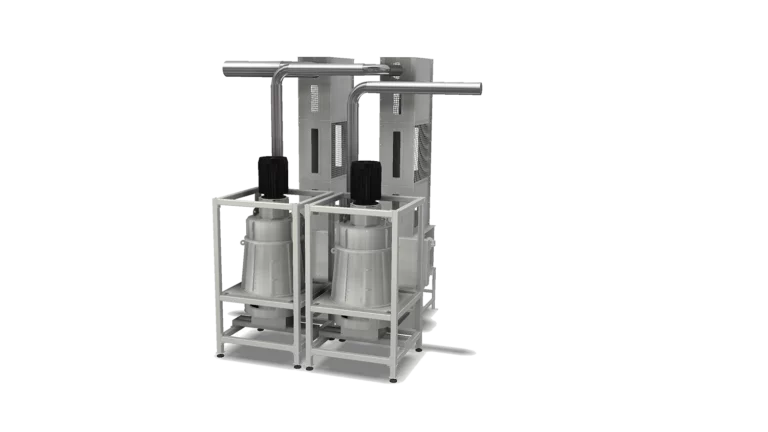

NW-600 roll S

Fully automatic process to make fiber ball from opened fibers. The fiber enters single rotor, from NW-540 silo with our frequency-controlled ventilator for optimal capacity

NW-601 roll D

Fully automatic process to make fiber ball from opened fibers. NW-601 roll d consists of 2 rotors for increased output. The fiber enters rotor 1,

NW-660 carding machine

Card working width is 2.000 mm, contact type metal detector at card feeding. Two feeding rollers: cleaning roll and flickering roll Main cylinder ø 1280

NW-662 carding machine

Refurbished card working width is 2.000 mm or 2.500 mm, contact type metal detector at card feeding. Two feeding rollers: cleaning roll and flickering roll

NW-684 filling line

The dosing silo provides constant fiber flow to the scales. Each scale has independent fiber filling, emptying to pillow and dosing pipe connections. Standard scales

NW-704 filling corner

Filling material feeding device for material that doesn’t need further processing. I.e readymade fiber ball in bags or ready to be used down and weather,

NW-706 sacking device

Device to be used to fill sack bags. System works continuously, while one bag is being filled another one can be unloaded and reloaded with

NW-720 large silo

Buffer silo 2000 mm in diameter and configurable height in 1000 mm sections. An actuator inside to accommodate more fiber and to outfeed fiber. If

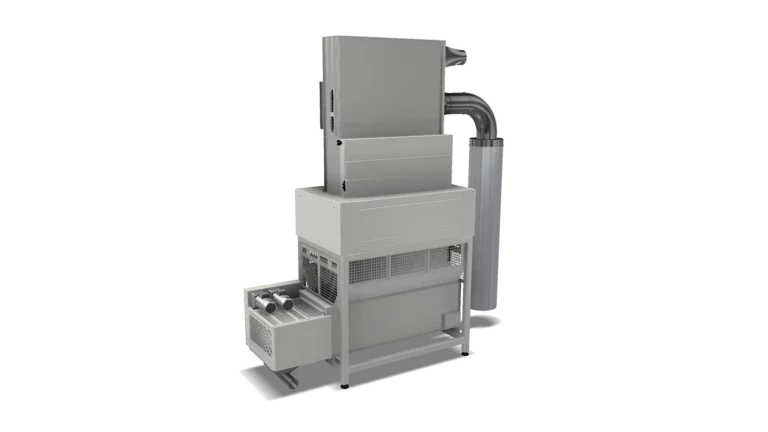

NW-740 filter units

Different filter units to be added to all our machines to filter process air before releasing into the production room. Keeps the production room cleaner

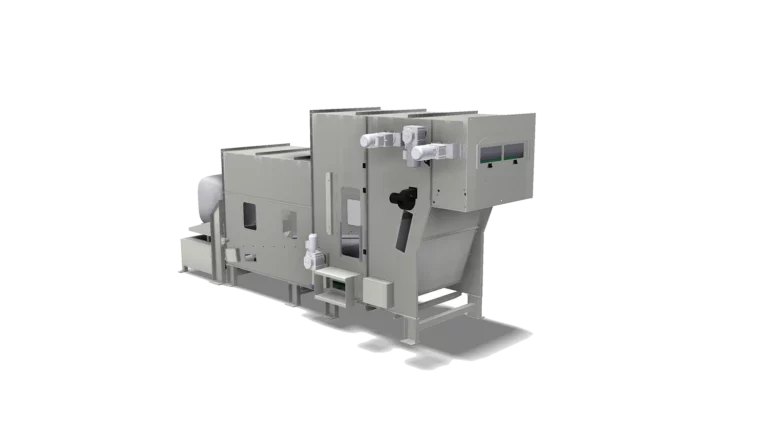

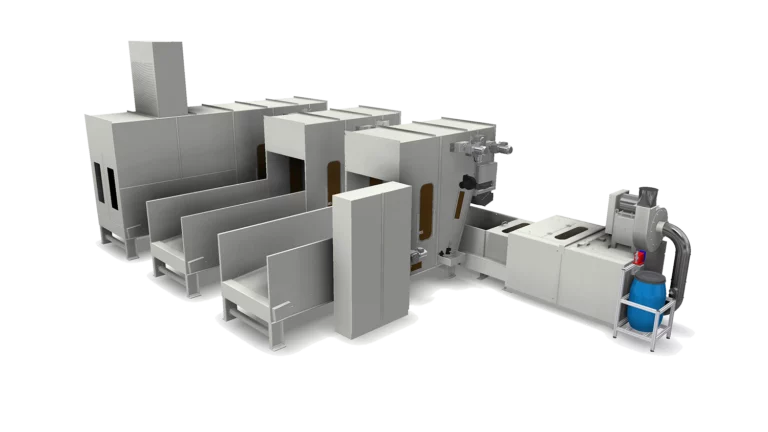

NW-760 fiber mixing line

The NW-760 fiber mixing line can have any number of bale openers which all can be equipped with scales. Each bale opener releases programmed amount

NW-780 cross lapper

A horizontal cross-lapper with side covers, short inclining infeed belt, horizontal belt, intermediate belt with an oscillating carrier. A second lapping belt with an oscillating

NW-800 continuous weight

Roller package on load cells, placed between volumetric feeder and before card infeed. AC motor with frequency inverter Parameter settings through touchscreen The system is

NW-820 volumetric feeder

A volumetric feeding box with feeding silo height 5.000 mm and working width 2.500 mm (or customized width). Pressure sensor for material level control Two

aBOUT OUR FIBRE PROCESSING LINES

The ACG Nowo equipment handles most fibers in the market. We have been creating custom-made automatic pillow filling lines for over 35 years, in consultation with some of the global major players in production of filled pillows. Our keyword is flexibility, to meet our customer´s demands when it comes to automatic pillow filling lines and fiber handling.

Our pillow production lines are carefully designed in cooperation with our customer, to use the factory layout in the most productive way and still reach high output and maintain the quality aspect.

If you are interested in a fully automatic pillow line, perhaps our concept “complete process – one supplier” is something to consider. By using ACG Nowo filling machines, we turn any of your raw material into desired filling. We offer either blow-filling or vacuum-filling machines and combined with ACG Kinna Automatic´s various automatic sewing and packing solutions, we cover your entire production chain by using automation.