quilt production machines

SWEDISH QUALITY MACHINES SINCE 1977

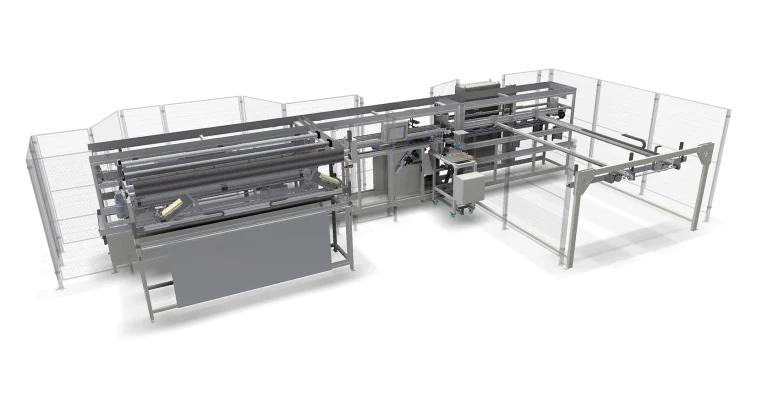

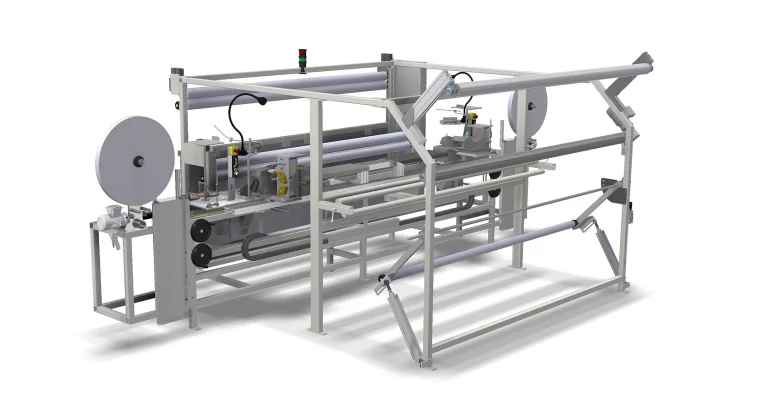

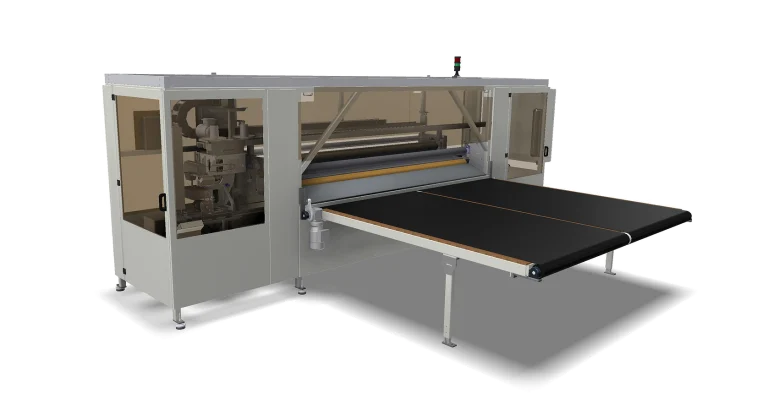

KA-1011 QUILT CROSS SIDE OVERLOCK SEWING

The quilted material is fed into the machine then measured, cut and transported to the sewing section where overlock finish on both ends is carried

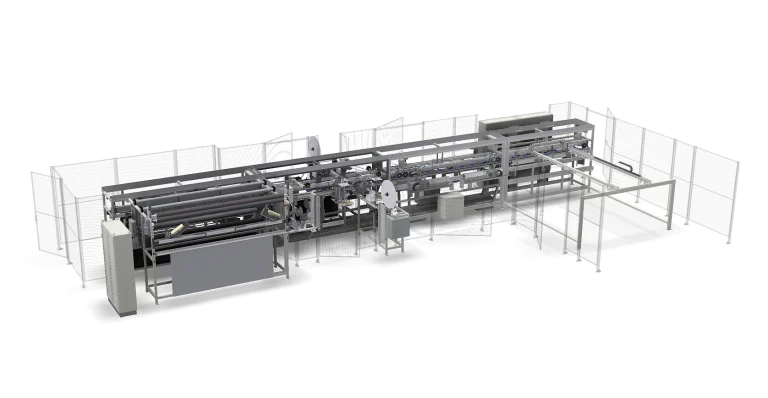

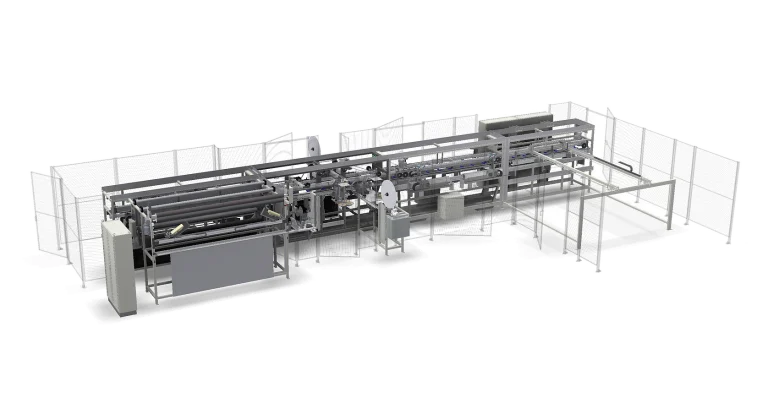

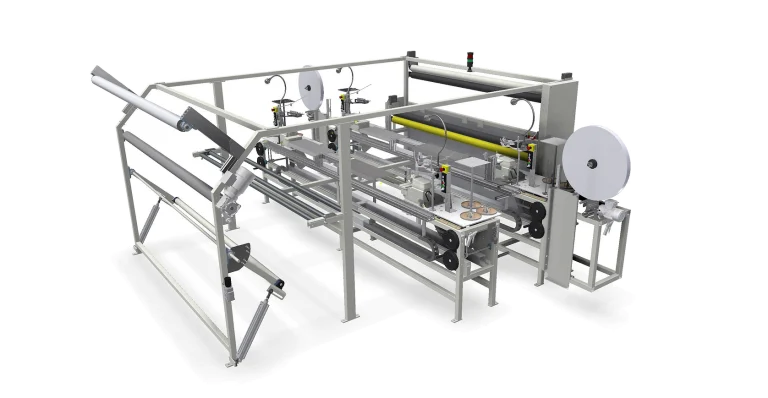

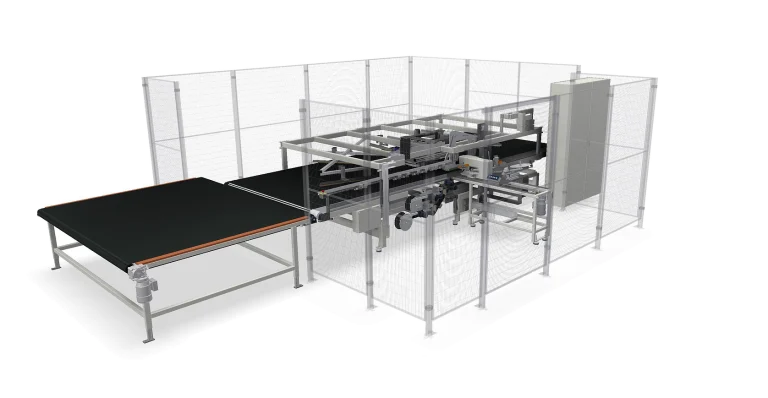

KA-1016 QUILT CROSS SIDE SEWING AND TAPE-EDGE FINISH WITH SQUARE CORNERS

The quilted material is fed into the machine then measured, cut and transported to the sewing section with tape-edge finish at both ends. Finished products

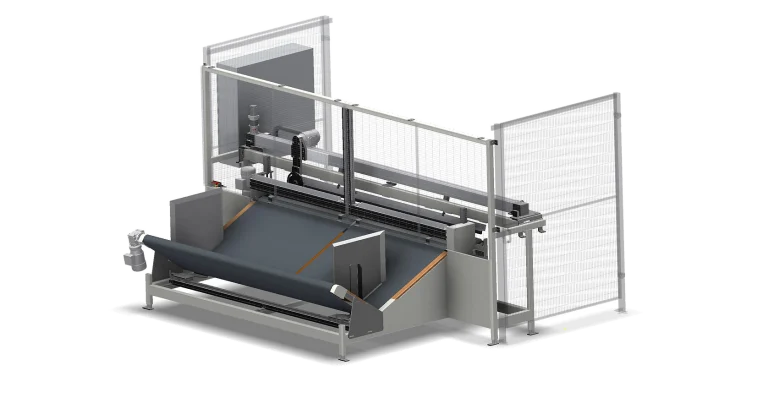

KA-1017 QUILT CROSS SIDE HYBRID SEWING SQUARE CORNER TAPE-EDGE AND OVERLOCK

The quilted material is fed into the machine then measured, cut and transported to the sewing section with tape-edge finish at both ends. Finished products

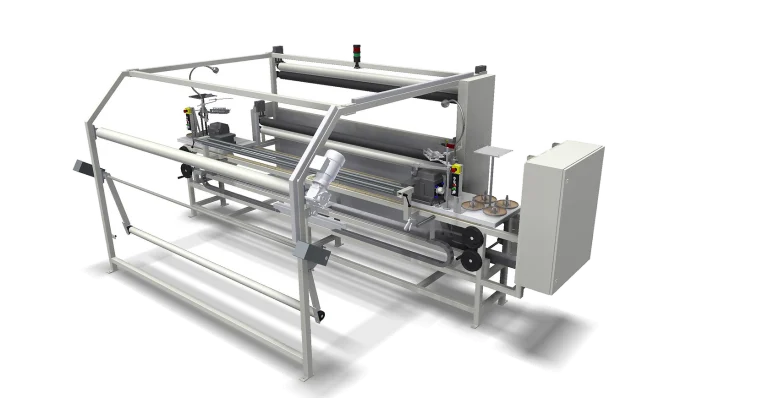

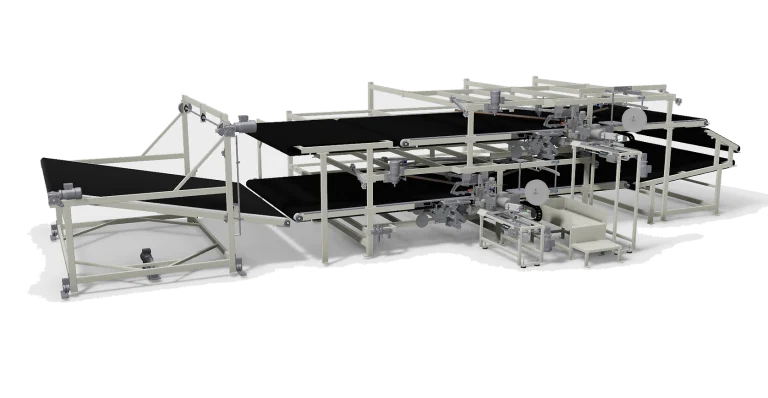

KA-1041 QUILT LONG-SIDE OVERLOCK SEWING

Machine with continuous overlock sewing of both long sides of the quilt. Should be placed in line with carder and multi-needle machine. 20 meters/minute sewing

KA-1046 QUILT LONG SIDE SEWING SQUARE CORNER TAPE-EDGE

This machine performs tape-edge finish along both sides of the material continuously. Should be placed in line with carder and multi-needle machine. 20 meters/minute sewing

KA-1047 QUILT LONG-SIDE SEWING HYBRID SQUARE CORNER TAPE-EDGE AND OVERLOCK

This machine should be placed after the multi-needle machine and consists of 2 long side sewing machines which handles both sides of the material continuously.

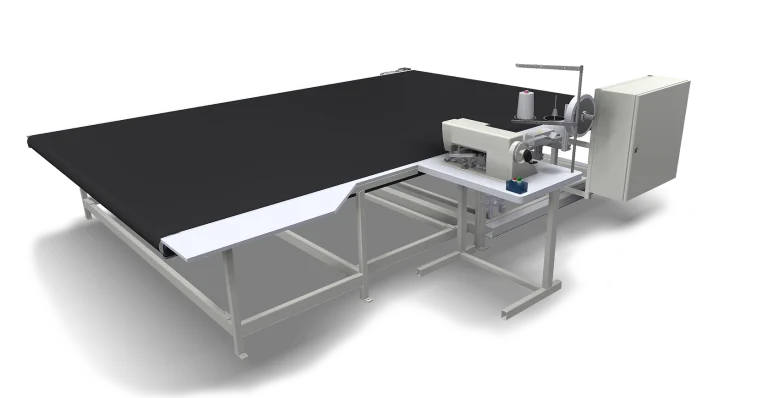

KA-115 QUILT SEWING TABLE

The conveyor is synchronized with the sewing machine during sewing and reverses at high speed to assist turning the product. Suitable for large products (quilts,

KA-144 FABRIC STANDS BEFORE MULTI-NEEDLE

Fabric stands to be placed between cross lapper and multi-needle. The fabric stand is equipped with a side movement system which enables the stand to

KA-145 QUILT TAPE-EDGING MACHINE WITH 2 LEVELS

Can be used in line or for manual feeding. The panel will be distributed by the adjustable conveyor to the first empty level and then

KA-166 QUILT CUTTING AND SEWING MACHINE

KA-166 is used to pre-sew before tape-edging. Simplifies manual tape-edge finish of quilts and mattresses. For multi-needle quilted and filled material. The material is measured

KA-167 STRIP CUTTER

The strip cutter can be integrated into any existing vacuum system beside ACG Kinna Automatic long side sewing machines. KA-167 is designed to be maintenance

KA-178 QUILT TAPE-EDGING MACHINE ROUND CORNERS

The quilt is manually loaded and positioned on the infeed conveyor before transport into the tape-edge station. All sides are finished with round corners. The

KA-201 METAL DETECTOR

KA-201 is integrated into ACG Kinna Automatic production lines. By adapting the detection system, it can offer several solutions how to handle faulty products when

KA-202 MATERIAL STAND AND CUTTING MACHINE

Material stand and cutting machine that can be used in several applications. Up to 8 cycles/minute Maximum width on material 260 cm Can be integrated

aBOUT OUR QUILT PRODUCTION MACHINES

At ACG Kinna Automatic we offer a wide range of quilt production machines which comes with different solutions, both as standard machines and in customized versions, for when a special customer automation request is necessary. Our machines can be used as stand-alone units or be integrated into production lines, existing or new.

What does your quilt production look like today?

Our range of quilt production machines includes automatic sewing of long side, cross side, and hybrid solutions where we combine overlock sewing with tape-edge finishing of the quilts. The quilt corners can be square or round shaped depending on what solution and finish your production demands. Our sales team can investigate how your production could increase its productivity and profitability. By integrating ACG Kinna Automatic’s quilt production machines and turning your production into automation solutions, we prepare your company for the future. Flexibility, high output, and machines with long lifespan and 24/7 accessible service support guarantees a great return on investment.