pillow and cushion stuffing machines

SWEDISH QUALITY MACHINES SINCE 1977

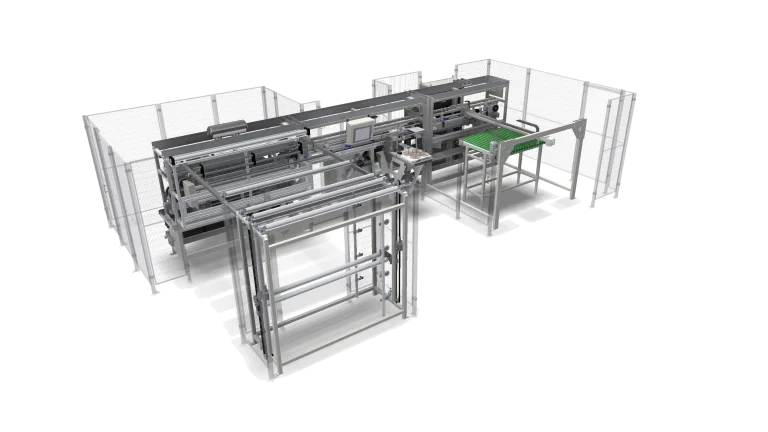

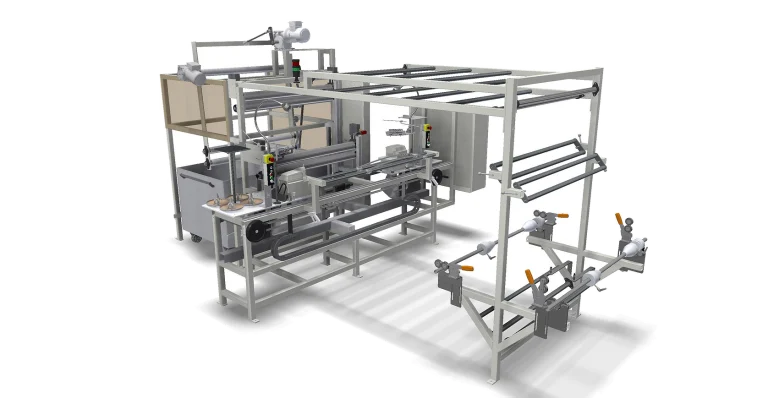

KA-1013 PILLOW TICK CROSS SIDE SEWING

The material trolley is placed inside the machine. Double length is measured, cut and transported at high speed into the sewing section where both ends

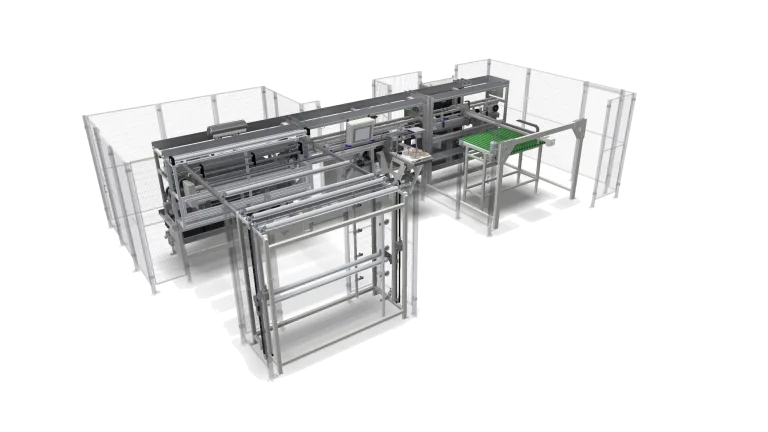

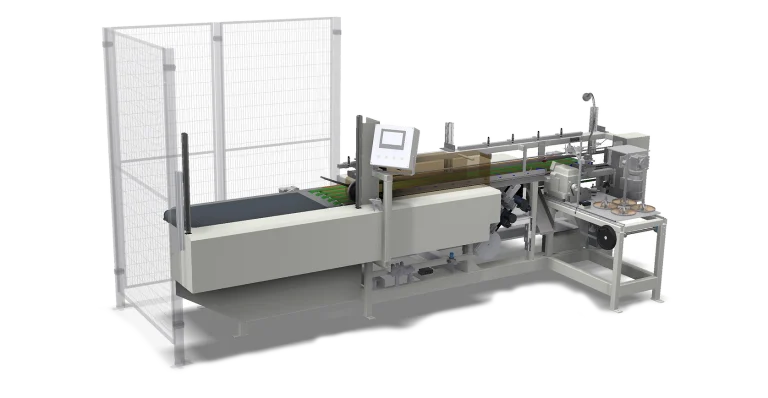

KA-1018 PILLOW TICK CROSS SIDE SEWING

This machine shall be integrated with KA-1048 or KA-1049. The tube is measured, cut and transported at high speed into the sewing section where one

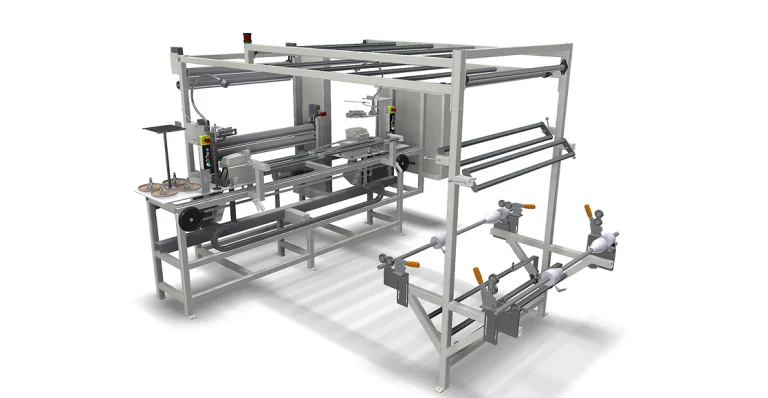

KA-1043 PILLOW TICK LONG SIDE SEWING

KA-1043 has one left and one right-handed sewing machine which sews together the two materials to a continuous tube. This tube is fed directly into

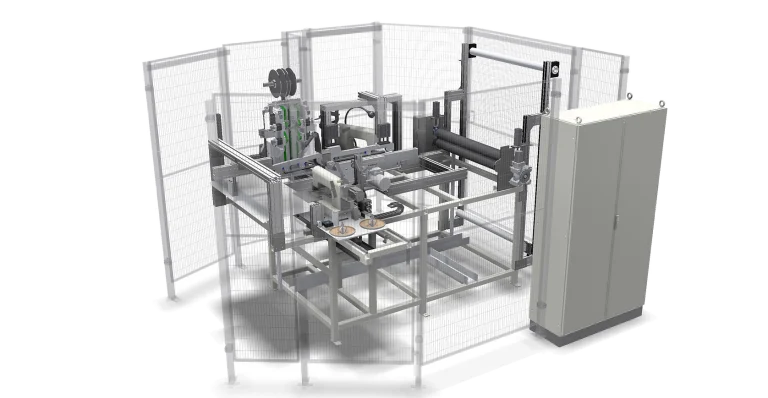

KA-1048 PILLOW TICK LS BLOW HOLE

The KA-1048 produces the short side of the pillow tick. On the left-hand side continuously sewing straight and attaching the labels either on top of

KA-1049 PILLOW TICK LS WITH PLEATING

KA-1049 is equipped with sewing machines on both sides which sews together the two materials to a continuous tube. The tube is pleated down into

KA-1082 PILLOW CLOSING MACHINE OVERLOCK SEWING

The operator places the filled pillow over 2 plates in the pillow closing machine. The machine is designed to close the open end of the

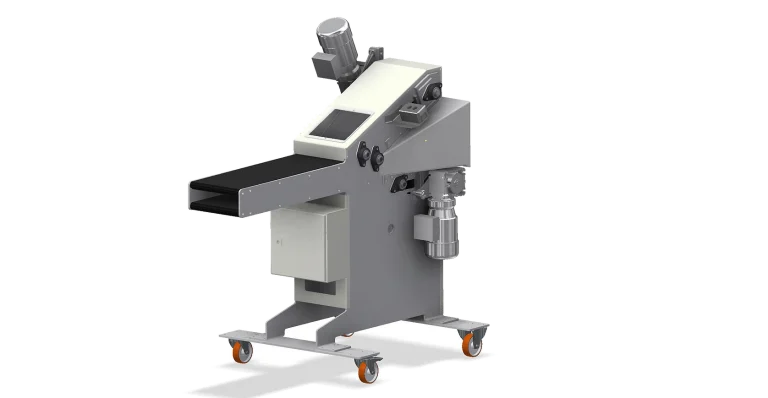

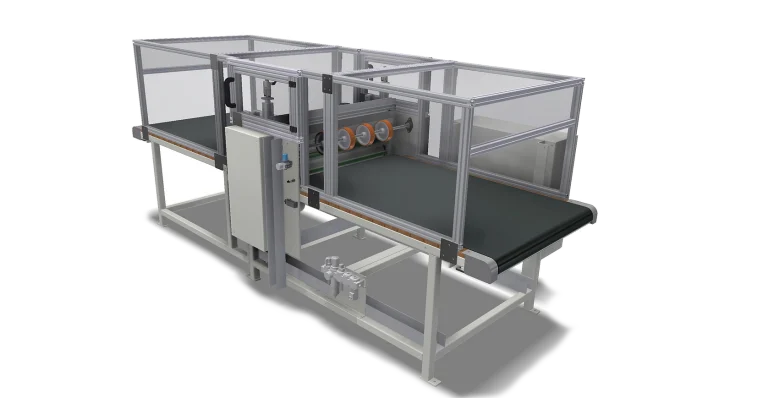

KA-1091 FILLING UNIT FIXED

This machine is used to fill rolled wadding into pillow ticks. Height on the nozzle fixed 12,5 cm Width on the nozzle as standard 31,5

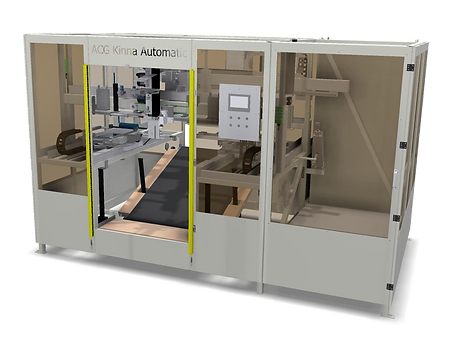

KA-1094 PILLOW SYSTEM FOR INSERTING FOAM AND LATEX

This system is used when inserting foam and latex pads into pillow covers. The infeed conveyor will automatically transport the pad into the filling unit.

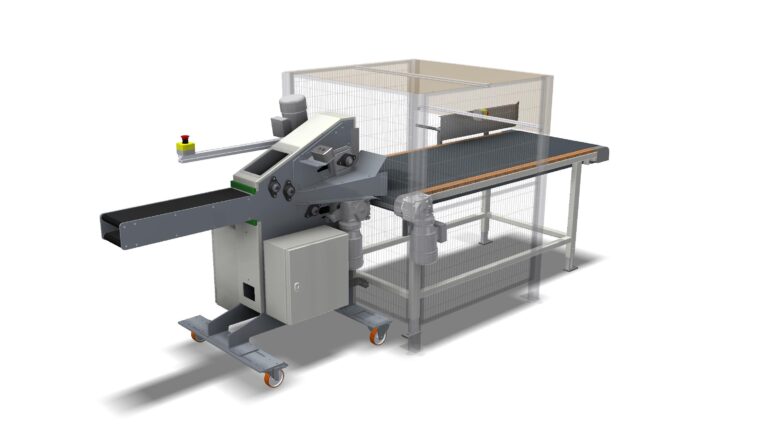

KA-122 LEVELLING STAND-ALONE

This machine helps the fibre to be evenly distributed inside the pillow after the sewing and filling by using a pressure technique. Maximum pillow width

KA-149 PILLOW TICK COMPACT

KA-149 automatically sews and stacks pillow ticks. At the infeed of the machine, two rolls of fabric are overlocked together creating the long sides, followed

KA-151 VACUUM TURNER

The purpose of the machine is to turn products inside out. Can be used for a number of different products as the nozzle can be

KA-152 CUTTING MACHINE FOR HALVING PRODUCTS

KA-152 is usually combined with the pillow tick machine KA-1013 (high production). The machine will cut and halve the sewn product, and in this way

KA-165 PILLOW CLOSING MACHINE LOCKSTITCH SEWING

The operator attaches the filled pillow on 2 hooks inside the machine. The machine will close the open end of the pillow using lockstitch sewing.

KA-201 METAL DETECTOR

KA-201 is integrated into ACG Kinna Automatic production lines. By adapting the detection system, it can offer several solutions how to handle faulty products when

aBOUT OUR STUFFING MACHINES

With over 45 years of experience, ACG Kinna Automatic is one of the world’s leading manufacturers of pillow stuffing machines. Our machine range offers various automation solutions and can be integrated into existing production lines or used as stand-alone pillow stuffing machines. Quality machines built in Sweden since 1977.

Our pillow stuffing machines provide automation solutions for the cutting and sewing of pillow ticks using overlock or lockstitch closing. Automatically sewing long side, cross side and blowhole opening including attachment of labels in different ways. To offer our customer flexibility, our machines can be supplied as a standard- or customized version.

Reach out today to our sales team and we can investigate how your company could automate your pillow production by using ACG Kinna Automatic´s pillow stuffing machines to increase efficiency and profitability. Today automation is a necessity for companies looking to survive and meet the future production demands of buyers worldwide. We at ACG Kinna Automatic are here and ready to guide you.