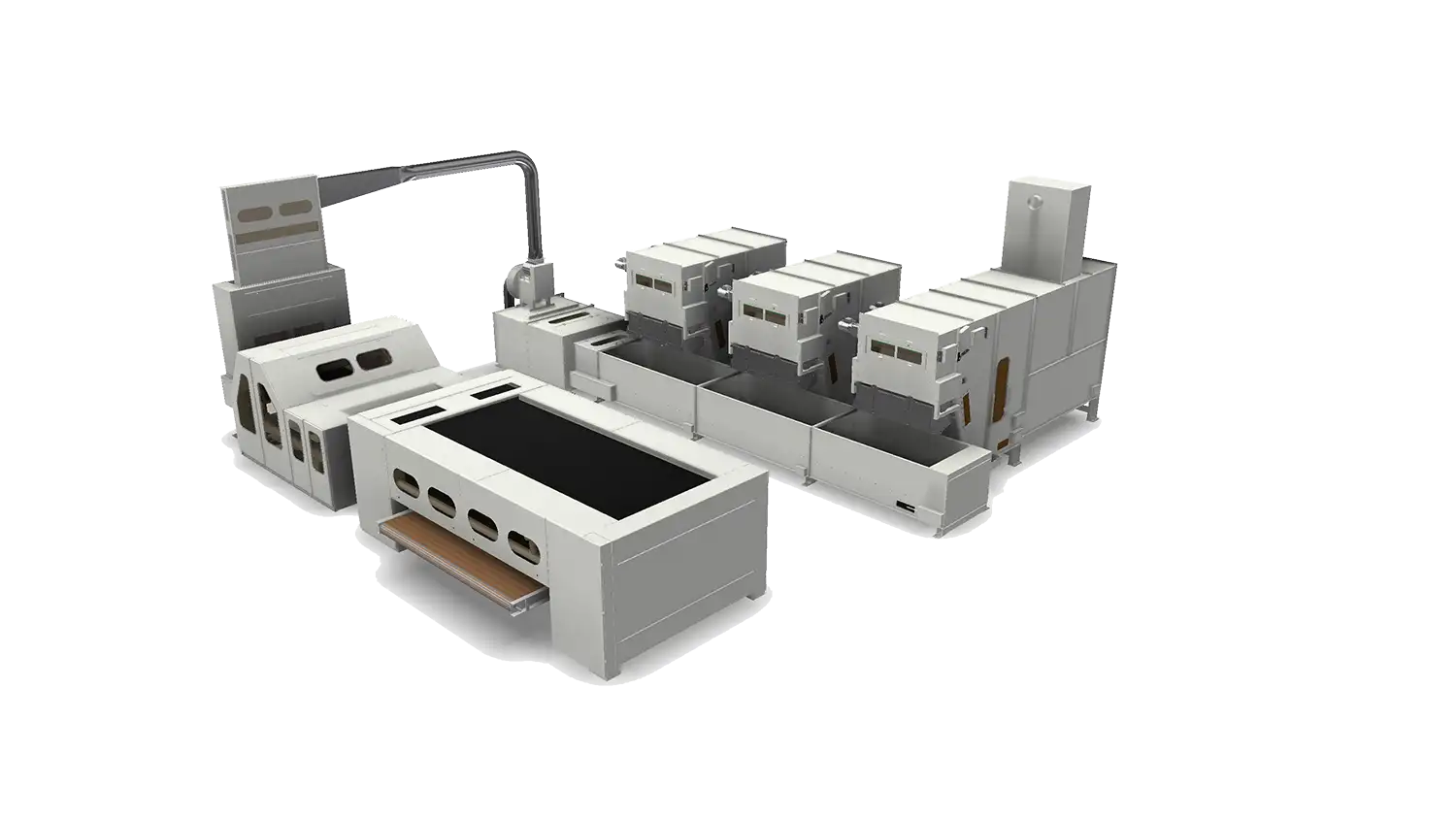

Raw material mixing / Bale opening

The current configuration has a mixing line with 3 bale openers where one has option to be filled by pneumatic transport system (production waste return). All bale openers are equipped with weight control and there can be any number of bale openers as well as feeders for non-fiber materials (foam chips, down and weather etc.)

Mixing / Pre-opening

Mixing/pre-opening is needed to have perfect mix of previously weighed materials. As an option, mixing can be replaced with a fine opener for blow fill applications or usage of direct feed from bale opener.

Infeed silos for carding machine

There are two main types of silos: volumetric silo - simple and cost effective but no actual weight control, and continuous weight control silo - more complex and expensive which has more precise weight control.

Cross lapper

Articulated conveyor type cross lapper is one of the most cost-efficient cross lappers for low to medium precision web lapping applications, i.e: quilted materials,

non-visible wadding products, in front of needle push applications, for carded roll filled products.